Control de Infraestructura de Tecnología de la Información (IT): Importancia y Mejores Prácticas

En la era digital actual, donde la tecnología de la información (IT) es el motor impulsor de casi todas las operaciones comerciales, el control efectivo de la infraestructura IT se ha convertido en una prioridad crítica para las organizaciones de todos los tamaños. Desde la gestión de redes y servidores hasta la protección de datos sensibles, el control de la infraestructura IT abarca una amplia gama de actividades y procesos diseñados para garantizar la disponibilidad, integridad y confidencialidad de los recursos y datos de una organización.

Este artículo explora la importancia del control infraestructura IT en el contexto empresarial actual, así como las mejores prácticas que las organizaciones pueden implementar para fortalecer sus sistemas y procesos de IT.

Importancia del Control de la Infraestructura IT

1. Seguridad de Datos

El control de la infraestructura IT es fundamental para garantizar la seguridad de los datos de una organización. Con el aumento de las amenazas cibernéticas como el malware, ransomware y phishing, proteger los datos sensibles se ha convertido en una prioridad crítica para las empresas. Implementar controles de seguridad adecuados en la infraestructura IT ayuda a prevenir brechas de seguridad y mitigar riesgos de pérdida o robo de datos.

2. Disponibilidad de Servicios

Una infraestructura IT bien controlada garantiza la disponibilidad de servicios críticos para el negocio. Esto implica mantener la disponibilidad de redes, servidores y sistemas de almacenamiento para evitar tiempos de inactividad no planificados que podrían afectar la productividad y la reputación de la empresa.

3. Cumplimiento Normativo

Muchas industrias están sujetas a regulaciones estrictas en cuanto a la protección y privacidad de datos, como el Reglamento General de Protección de Datos (GDPR) en la Unión Europea o la Ley de Portabilidad y Responsabilidad del Seguro Médico (HIPAA) en Estados Unidos. El control de la infraestructura IT ayuda a garantizar el cumplimiento de estas regulaciones al implementar medidas de seguridad y privacidad adecuadas.

4. Eficiencia Operativa

Una infraestructura IT bien controlada contribuye a la eficiencia operativa al optimizar el rendimiento de los sistemas y procesos de TI. Esto incluye la gestión proactiva de recursos, la automatización de tareas repetitivas y la identificación y resolución rápida de problemas de IT.

5. Gestión de Costos

El control efectivo de la infraestructura IT también ayuda a gestionar los costos asociados con la tecnología. Al optimizar el uso de recursos y evitar gastos innecesarios, las organizaciones pueden maximizar su retorno de inversión en IT y mejorar su rentabilidad.

Mejores Prácticas para el Control de Infraestructura IT

1. Evaluación de Riesgos

Antes de implementar cualquier medida de control, es importante realizar una evaluación exhaustiva de los riesgos de seguridad y cumplimiento asociados con la infraestructura IT de la organización. Esto incluye identificar posibles vulnerabilidades, evaluar el impacto de posibles amenazas y determinar la probabilidad de ocurrencia de eventos adversos.

2. Políticas de Seguridad

Desarrollar y aplicar políticas de seguridad sólidas es esencial para controlar la infraestructura IT. Estas políticas deben abordar aspectos como la gestión de contraseñas, el acceso a recursos de IT, la protección de datos y la gestión de incidentes de seguridad. Es importante que estas políticas sean claras, específicas y aplicables a todos los usuarios y sistemas de la organización.

3. Gestión de Acceso

Controlar quién tiene acceso a los recursos y datos de IT es fundamental para garantizar la seguridad y la privacidad. La implementación de controles de acceso basados en roles, autenticación multifactor y monitoreo de actividad de usuario ayuda a prevenir accesos no autorizados y proteger la información confidencial.

4. Actualizaciones y Parches

Mantener todos los sistemas y software de IT actualizados con los últimos parches de seguridad es una práctica fundamental para mitigar riesgos de seguridad. Las vulnerabilidades de seguridad conocidas suelen ser explotadas por los atacantes, por lo que es importante implementar un proceso de gestión de parches que garantice la aplicación oportuna de actualizaciones críticas.

5. Copias de Seguridad y Recuperación de Datos

Realizar copias de seguridad regulares de los datos críticos y tener un plan de recuperación de desastres en su lugar son aspectos esenciales del control de la infraestructura IT. En caso de fallo del sistema, error humano o ataque cibernético, las copias de seguridad permiten restaurar los datos y minimizar el tiempo de inactividad.

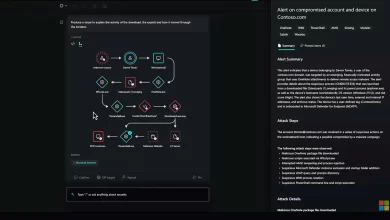

6. Monitoreo y Detección de Amenazas

Implementar herramientas de monitoreo y detección de amenazas permite a las organizaciones identificar y responder rápidamente a actividades sospechosas en su infraestructura IT. Estas herramientas pueden ayudar a detectar intrusiones, malware y otros ataques cibernéticos antes de que causen un daño significativo.

7. Educación y Concienciación

La educación y concienciación de los empleados sobre las mejores prácticas de seguridad de IT son fundamentales para fortalecer el control de la infraestructura IT. Proporcionar formación regular sobre la identificación de amenazas cibernéticas, el uso seguro de contraseñas y la prevención de ataques de phishing puede ayudar a reducir el riesgo de incidentes de seguridad causados por errores humanos.

Conclusiones

El control efectivo de la infraestructura IT es fundamental para garantizar la seguridad, disponibilidad y eficiencia de los sistemas y datos de una organización. Al implementar las mejores prácticas de control de IT, las organizaciones pueden mitigar riesgos, cumplir con regulaciones y optimizar su rendimiento operativo en un entorno empresarial cada vez más digitalizado y competitivo.